Home > Products > Plastic Profile Extrusion Line > CE approved wood plastic profile production line

CE approved wood plastic profile production line

- 20 Unit / Units per Month

- Shanghai

- T/T

-

CE ISO SGS approved high performance wpc profile production line

-

CE approved high performance wpc profile production line

-

CE approved PVC window profile extrusion line

-

CE approved high performance abs profile production line

-

CE approved soft pvc profile production line

-

CE approved high performance pe profile production line

Product Details

| Condition: | New | Place of Origin: | Jiangsu, China | Brand Name: | CHICHENG |

| Model Number: | SJSZ | Certification: | CE |

Product Description

Specifications

wood plastic profile production line1.Wood&PVC extruding

2.Twin screw extruder

3.Low power consumtion

4.SGS,CE,ISO9001:2008

wood plastic profile production line

The door and window profile is widely used as window and door decorative material,which is made of wood&PVC powder. With modern technology and optimized design, it has the property of high output capacity, long life and plastic evently.

This production line is designed for extrusion of wood plastic door and window profiles and cross-section communication cable pipes, Aluminum-plastic composite profiles, etc. It has stable plastification, high output, low sheering force, long life service and other advantages. wpc profiles can be used in the building industry and home or office.

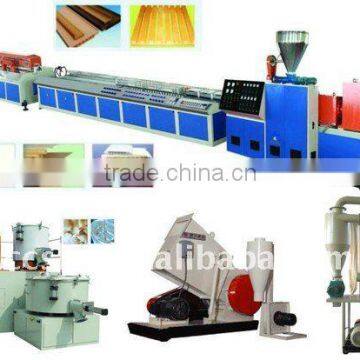

The production line consists of control system, conical twin screw extruder, extrusion die, calibration unit, haul-off unit, film covering machine and stacker. The extruder is equipped with alternating-current converter, imported temperature controllers. The calibration unit’s pump and haul-off unit’s reducer are the famous brand products.

After simple changing of the die and crew, it also become possible to produce foam profiles.

It has the characters of high quality, good plasticizing effect, lower power consumption.

Main Technical parameter

| Model | Max.Width mm | Extruder | Assistance Power | Output kg/h | Speed m/min |

| SY-180 | 180 | 51/105 | 22 | 80-100 | 0.6-6 |

| SY-240 | 240 | 65/132 | 28 | 180-240 | 3-3.5 |

| SY-300 | 300 | 80/172 | 34 | 300-350 | 4-5 |

The whole production line includes the following major parts:

1.SRL-Z300/600 wood PVC high speed mixing machine

2.SJSZ-80/156 conical twin screw exruder

3.WPC profile moulds(extruding and forming,mould temperature controller)

4.Vacuum forming machine

5.Hauling off machine

6.Stacker

Pls note the above price excluding the moulds.

wood plastic profile production line

Twin conical screw extruder

Vacuum forming table

Haul off machine

Cutting machine

wpc profile products

Contact Us

- Suzhou New Chicheng Machinery Co., Ltd.

- Contact nameLily WU Chat Now

- Phone0086-512-58603188

- AddressHongfu Village, Jinfeng Town, Zhangjiagang

Product Categories

-

CE approved pvc window and door profile production line

-

PVC profile production line

-

PVC window profile machine

-

WPC Profile Production Line

-

CE approved pvc window and door profile extrusion line

-

CE approved wpc window and door profile production line

-

CE approved pvc window and door profile extrusion line

-

CE approved high quality PVC profile production line

-

CE approved high performance PVC profile making machine

-

CE approved high performance PVC profile machine

-

CE approved PVC window profile production line

-

CE approved PVC window profile extrusion line

Popular Searches

- plastic extruder

- extrusion machine

- twin screw extruder

- aluminum tube production line

- Foam Board Equipment

- production line

- extruding machine

- Production Equipment

- extrusion line

- Belt Making Machinery

- Extruder Machine

- Pet Strap Making Machine

- Pet Belt Making Machine

- Bubble Film Making Machine

- Cable Manufacturing Equipment

- plastic extrusion

Recommended Products

- Pelletizing Die Plate for Granulation in Petrochemical PP PE Plant

- Knife Rotor for extruder Pelletizing Knife Holder for PP PE underwater granulators

- Granulation Die Plate for Granules Making Machine of Twin Screw Extruder in PP PE Plant

- PP honeycomb borad extrusion line

- Twin Screw Extruder Die Plate for Granules Making Machine in PP PE Plant

- vacuum cleaner flexible hose produce machine

- Underwater Pelletizing Unit Use Knife for Plastic Granules

- Pelletizer Die Plate for Polyolefin Pelletizing Machine in PP PE Petrochemical Plant

- Fixed Pelletizing Knife Rotor for Plastic PP PE underwater granulation

- Cutter Blade for Plastic Resins Granulation Metal-ceramic Composite Pelletizer Knife

- Granulation Die Plate for Manufacturing PP PE EVA Granules in Petrochemical Industry

- Extrusion Machinery Spare Parts Hob Used in the Process of Polyester Granulation

Find Similar Products By Category

- Machinery > Plastic & Rubber Machinery > Plastic Product Making Machinery > Plastic Extruders