Home > Products > briquette press > Carbon Residue Briquette Plant(0086-15978436639)

Carbon Residue Briquette Plant(0086-15978436639)

- 500 Set / Sets per Month

- Qingdao

- T/T L/C D/P D/A Credit Card PayPal Cash Escrow Other

- 7 days

You May Like

-

Carbon Residue Ball Press Machine(0086-15978436639)

-

Carbon Residue Briquette Press Machine(0086-15978436639)

-

Carbon Residue Briquetting Machine(86-15978436639)

-

Carbon Residue Roller Press Machine(86-15978436639)

-

Carbon Residue Briquette Roller Machine(0086-15978436639)

-

China Charcoal Making Plant Manufacturers and Factory(86-15978436639)

Product Details

| Brand Name: | Shisheng Machinery | Place of Origin: | China | Model Number: | XM500 |

| Certification: | ISO9001/CE | After-sales Service Provided: | Engineers available to service machinery overseas | Warranty: | one year |

| Dimension(L*W*H): | 1730*1860*1940mm | Production Capacity: | 7.5-8.5t/h | Condition: | New |

| Power(W): | 37kw | Motor Type: | AC Motor |

Packing and Delivery: (1)Seaworthy packing as per export container rules, bigger items loose stuff in container and small parts will be tied up in a bundle put into steel boxes or plywood boxes. (2)Delivery will be arranged based on busy or low producing season in our factory, single set machine is normally not more than 40 days, production line is in 2 month. (3)Dispatch experienced engineers to installation & commission, and training;

Product Description

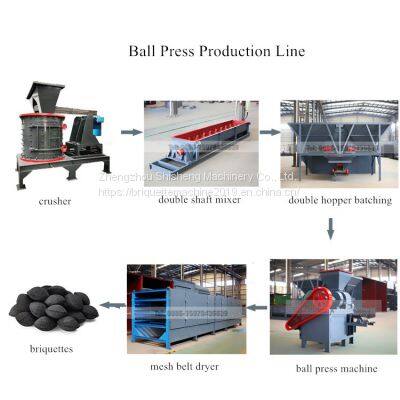

Carbon Residue Briquette Plant

Carbon Residue Briquette Plant Introduction:

Carbon Residue Briquette Plant is an ideal mechanical equipment designed for processing powdery materials, such as nonferrous metal powder and mineral powders. After being made into briquettes, these wasted powders can be reused in various industries, hence increasing additional value of mineral resources. Carbon Residue Briquette Plant is proud of that the finished briquettes come with high intensity, great convenience for transportation and various shapes. Custom-made shape is also available.

Carbon Residue Briquette Plant Customer Reminding:

(1)For Carbon Residue Briquette Plant, if feeding material is bigger, better to crusher first before briquetting.

(2) If material is in high moisture (higher than 15%), a dryermachine would be necessarily. But If you prefer to use press machine, the moisture should be less than 5%, also based on materials’ performance.

(3) Generally, to add some binder/adhesive into the raw materialin briquetting. The final briquette will be strong, high density, and better quality.

(4) The final briquettes can be dried naturally under the sunshine, or through mesh belt dryer and chain plate dryer accordingly to customer investment budget. But if is in capacity of 8-10t/h or more, we will suggest second one.

Carbon Residue Briquette Plant Notify:

(1)We not only produce a single set of Carbon Residue Briquette Plant, but also complete production line, including batching machine, wheel grinding mixer, double shaft mixer, vertical crusher and briquette dryer, large angle belt conveyor, etc.

(2) All of machines have passed ISO and CE certificate, so machine quality is totally qualified.

(3) Carbon Residue Briquette Plant is proud of that the finished briquettes come with high intensity, great convenience for transportation and various shapes.

Carbon Residue Briquette Plant Technical Parameter:

XM Series Coal Briquetting Machine

| Model | Reducer | Ratio | Roller Size(mm) | Main Shaft Speed(r/min) | Matched Power(kw) | Capacity(t/h) | Pressure Type |

| XM290 | ZQ350 | 1:31.5 | 290*200 | 12-14 | 5.5 | 0.9-1.0 | Constant Pressure |

| XM360 | ZQ350 | 1:31.5 | 360*250 | 12-14 | 7.5 | 1.5-2.0 | Constant Pressure/Hydraulic Pressure |

| XM400 | ZQ400 | 1:31.5 | 400*250 | 12-14 | 7.5 | 2.5-3.5 | |

| XM430 | ZQ400 | 1:31.5 | 430*250 | 12-14 | 11 | 3.5-4.5 | |

| XM500 | ZQ650 | 40.17 | 500*470 | 10-12 | 37 | 7.5-8.5 | |

| XM650 | ZQ850 | 40.17 | 650*470 | 9-11 | 45 | 9-10 | |

| XM750 | ZQ1000 | 40.17 | 750*570 | 9-11 | 90 | 13-14 | |

| XM850 | ZQ1250 | 50 | 850*570 | 8-10 | 110 | 15-17 | |

| Remarks: Above capacity is based on material specific gravity 0.8, briquette size: φ50*33mm | |||||||

| Roller material is 65Mn, high chrome alloy and 9Cr2Mo | |||||||

| According to different material adjust machine parameter to meet customer production | |||||||

KF Series Mineral Powder Briquetting Machine

| Model | Reducer | Ratio | Roller Size | Main Shaft Speed(r/min) | Matched Power(kw) | Capacity(t/h) | Pressure Type |

| KF500-371-280 | ZQ500 | 40.17 | 370*280 | 8-10 | 11 | 6.5-7.5 | Constant Pressure/Hydraulic Pressure |

| KF650-500-300 | ZQ650 | 40.17 | 500*300 | 8-10 | 37 | 8.5-9.5 | |

| KF850-650-300 | ZQ850 | 40.17 | 650*300 | 8-10 | 55 | 10.5-11.5 | |

| KF1250-750-350 | ZS1250 | 50 | 750*350 | 7-9 | 110 | 13.5-14.0 | |

| KF1450-850-350 | ZS1450 | 50 | 850*350 | 7-9 | 132 | 15.0-16.0 | |

| KF560-1000-350 | ZSY560 | 50 | 1000*350 | 7-9 | 150 | 17.0-20.0 | |

| Remarks: Above Capacity is based on material specific gravity 2, briquette size:φ50*33mm | |||||||

| Roller material is 65Mn, high chrome alloy and 9Cr2Mo. | |||||||

| According to different material adjust machine parameter to mmet customer production | |||||||

YHG Series Dry Powder High Pressure Briquetting Machine

| Model | YHG-0.5 | YHG-1.5 | YHG-3.0 | YHG-5.0 | YHG-8.0 | YHG-10.0 |

| Roller Diameter(mm) | φ299 | φ367 | φ522 | φ738 | φ760 | φ858 |

| Roller Width(mm) | 180 | 183 | 196 | 210 | 225 | 300 |

| Capacity(t/h) | 0.5 | 1.2-1.4 | 2.5-3.0 | 4.5-5.5 | 7.5-8.5 | 8.0-9.5 |

| Main Reducer | ZQ650 | ZQ850 | ZS1250 | ZS1450 | ZS1650 | ZS1650 |

| Main Motor | 18.5 | 37 | 55 | 75 | 90-110 | 110-132 |

| Pre-pressure Motor(kw) | 7.5 | 11 | 15 | 18.5 | 18.5 | 22 |

| Pre-pressure Reducer | WHC-125 | WHC-160 | WHC-200 | WHC-210 | WHC-210 | WHC-250 |

| Remarks: Above capacity is based on material specific gravity 1.3, briquette size: φ35*30*20mm | ||||||

| Roller material adopts 9Cr2Mo | ||||||

| Pre-pressure motor is speed motor | ||||||

Company Profile

The factory is located in Zhengzhou Economic and Technological Industrial Development Zone, covering an area of more than 130 acres. It has two standardized heavy-duty industrial plants with 10,000 square meters, more than 150 large and medium-sized metal processing, riveting and assembly equipment, and more than 130 online employees, including There are more than 30 management cadres and engineering and technical personnel with intermediate and senior titles. The company has successively introduced advanced technologies and processes from the United States, Germany, Japan, Australia and other countries, established an internationally advanced production line and a first-class modern testing base, and established a sand and gravel machine research room, a grinding machine research room, and a research room for mineral processing equipment room. The company has rapidly grown into a production and sales base of mining machinery in China with scientific management methods, manufacturing processes for excellence, and innovative manufacturing concepts. Do your best to continuously improve and make it increasingly international.

Contact Us

- Zhengzhou Shisheng Machinery Co., Ltd.

- Contact nameYang Chat Now

- Phone86-371-66589366

- AddressZhongyuan, Zhengzhou, Henan

Product Categories

New Products

-

Small Briquette Ball Press Machine Charcoal Briquette Making Machine(86-15978436639)

-

Large Capacity Coal Charcoal Powder Briquette Making Machine Price(86-15978436639)

-

Factory Supply Coal Ball Making Machine Briquette Charcoal Machine(86-15978436639)

-

Professional Manufacture High Pressure Charcoal Ball Press Machine Automatic Coal Ball Briquette Making Machine price(86-15978436639)

-

Charcoal Coal Pellet Making Machine(86-15978436639)

-

Small Briquette Ball Press Machine Charcoal Briquette Making Machine(86-15978436639)

-

Briquettes Making Wood Charcoal Briquette Machine(86-15978436639)

-

Small Charcoal Briquette Making Machine Coal Briquette Making Machine Price(86-15978436639)

-

Large Capacity Coal Charcoal Powder Briquette Making Machine Price(86-15978436639)

-

Factory Supply Coal Ball Making Machine Briquette Charcoal Machine(0086-15978436639)

-

Professional Manufacture High Pressure Charcoal Ball Press Machine Automatic Coal Ball Briquette Making Machine Price(0086-15978436639)

-

Roller Ball Press Pillow Shape Charcoal Briquette Machine Coal Charcoal Oval Shape Briquette Making Machine(86-15978436639)

-

Hydraulic Cooking Coal Coke Dry Powder Lime Fines Charcoal Briquette Making Machine Price(0086-15978436639)

-

Indurteial BBQ Coal/Charcoal Powder Briquettes Making Machine, Coal Ball Press Machine(0086-15978436639)

-

Charcoal Coal Briquette Making Machine(86-15978436639)

-

Biomass BBQ Charcoal making machine Coal Powder Ball Press Machine/Briquette Making Machine(0086-15978436639)

-

Cheap Automatic Wood Charcoal Briquette Making Machine Price(0086-15978436639)

-

25 Years Original Manufacturer Briquette Charcoal Making Machine(0086-15978436639)

-

High Pressure Efficiency Ball Press Coal Large Capacity BBQ Charcoal Briquettes Making Machine(0086-15978436639)

-

Charcoal Ball Eggs Briquette Pressing Machine Ball Shape(86-15978436639)

-

Briquette Making Machine Price 30 Years Production Experience(86-15978436639)

-

Charcoal Dust BBQ Charcoal Briquette Making Machine/Coal Powder Ball Press Machine for Sale(0086-15978436639)

-

Best Price Sawdust Briquette Charcoal Making Machine For Cooking Biomass Wood Fuel Compressed Sawdust Logs Briquettes Machine(86-15978436639)

-

Coal Pellet Briquette Making/Charcoal Ball Briquette Machine Charcoal Aluminium Press Briquetting Machine for Sale(86-15978436639)

Find Similar Products By Category

- Machinery > Energy & Mineral Equipment > Mining Machinery > Briquette Machines